Mini Masterclass: Why Full-Grain Leather?

Leather has long been revered for its durability, timeless elegance and versatility, making it a preferred material for crafting high-end handbags, briefcases, and luggage. However, with the mass-production of these accessories has come a drive for more and more ways to economise on their creation, to provide lower prices to the consumer, greater margins to the brands (often needing to cover many stages and continents in their manufacture) and – perhaps less apparent to those consumers, – uniformity to help manage customers’ expectations and reduce returns and complaints.

At Tusting, we are very clear to point out that our goods are made from full-grain leather. This is because we want you to know that we are using the highest quality of leather, but what exactly is full-grain leather, and what are the pros and cons of this best grade of leather?

Full-grain Leather

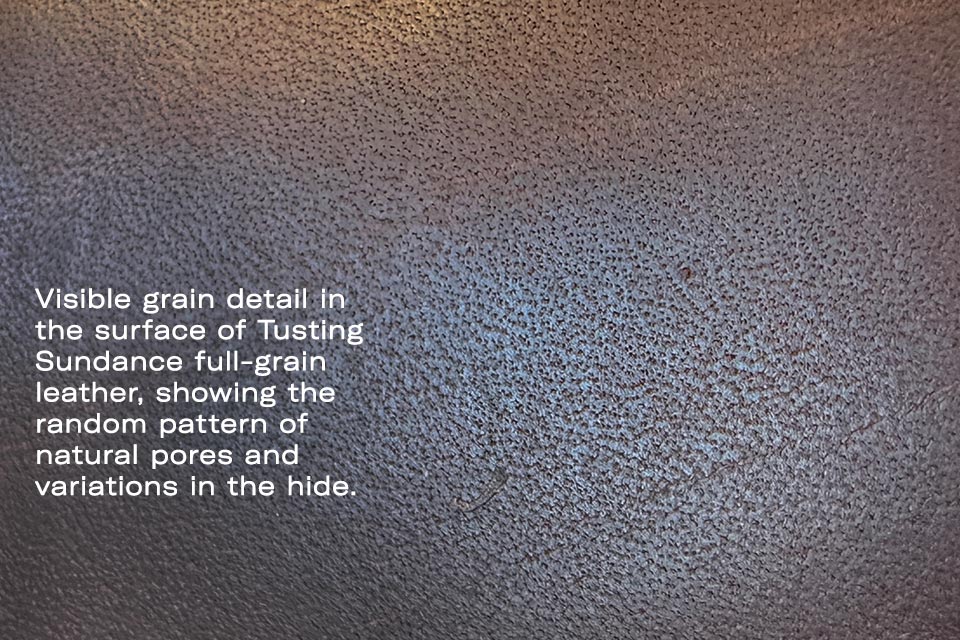

As discussed more fully in our blog about split leather, full-grain leather has a fully intact top surface, complete with all its natural marks and variations, but also the maximum strength and resilience that nature has given it.

Full-grain leather has a natural aesthetic, retaining the genuine markings and characteristics of the animal hide. We love this – it holds true to the raw beauty of the leather and gives each product a unique and undeniably authentic appearance which a consumer can identify with – it makes their purchase just a little different from any other.

Known for its robustness, full-grain leather is resistant to wear and tear, ensuring that products made from it retain their integrity over time. This longevity can otherwise be described as natural sustainability; longevity alone is a key factor in reducing production of lesser-quality goods, but also means greater value for money for the consumer. The ability to repair a product, and the economics of doing so, are also increased if it was made from such high-quality materials.

It’s not all easy though – natural imperfections in full-grain leather can be challenging for us makers; achieving a consistent enough appearance across multiple products requires careful selection when cutting the leather and expert craftsmanship in the making. This labour and skill-intensive process, coupled with the need for high-quality (expensive!) hides, necessarily increases production costs.

On top of this, consumers cannot simply take a high price as a guarantee of quality, since so many very expensive leather-goods brands do not use full-grain leather. Further, the example set by those brands actually leads consumers to believe that high quality leather should be free of visible character and variations…

Corrected Leather

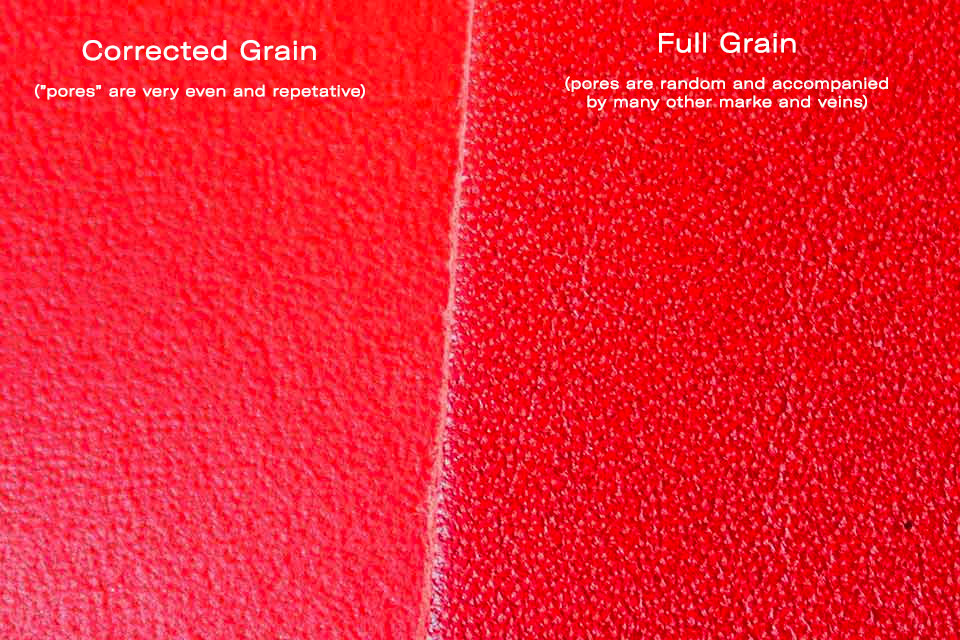

The most frequently used alternative to full-grain leather in leather-goods is ‘corrected’ leather. This undergoes processes like sanding and buffing to remove imperfections in the grain, resulting in a smoother and more uniform surface. The resultant sanded surface must then be coated with a ‘replacement’ top surface which is usually polyurethane-based and is often then embossed with a fake grain to replace the sanded-off one.

This fake grain is needed because, unlike wood, where the grain pattern and strength runs right through the material (and sanding can only smooth and improve the visual appearance of the wood’s grain) leather has a very thin top surface which is essential to see it’s natural character. The surface grain is also needed for maximum strength and longevity, which is not replaced by the ‘new’ coatings applied to corrected leather, meaning that products made from corrected leather will likely not withstand wear as well as those crafted from full-grain leather.

Through using corrected leather, manufacturers can achieve a consistent look, meeting market demands for standardised aesthetics – some consumers do prefer a uniform and smooth appearance and may find corrected leather more appealing.

Makers can also improve their profit margins, since corrected leather often utilises lower-grade hides or those with more blemishes, making it a more cost-effective choice. This can lead to more affordable products for consumers, however those comsumers sadly do not often know they are being sold compromised quality.

Happily for us here at Tusting, some consumers do perceive the lower quality of corrected leather, as it lacks the warmth of touch and natural imperfections that contribute to the charm of full-grain leather. They also appreciate that corrected leather has limited longevity – it often does not hold up well over time, with durability issues bringing the need for more frequent replacements.

In summary, full-grain leather offers a premium and enduring material for creating leather-goods. It does require that its consumers understand that the natural variations in it are valued features that speak of its provenance and authenticity. Full-grain leather appreciates a little more care and maintenance over time (after all, there is little point in trying to feed the plastic layer of corrected leather!) but will reward the user with a longer life and plenty of individual charm.