A favourite handbag, a trusty work briefcase: everyday essentials that stay by our side whatever life throws at us. But we often don’t give much thought to where these valued items come from. It’s not surprising nowadays to find that you can’t remember where you picked up your latest accessory.

TUSTING is different. Our customers value the heritage of our name and the craftsmanship of our products. And we feel the same: our family is dedicated to creating exquisite leather bags that will delight you for years to come.

This is our story.

-

EARLY HISTORY

To really understand where TUSTING came from, we begin our story in the 1870s. The development of the sewing machine had begun to transform the shoe-making industry forever. No longer having to sew tough leather pieces together manually, shoemakers were free to explore ambitious – and blessedly comfortable! – new designs.

-

20TH CENTURY

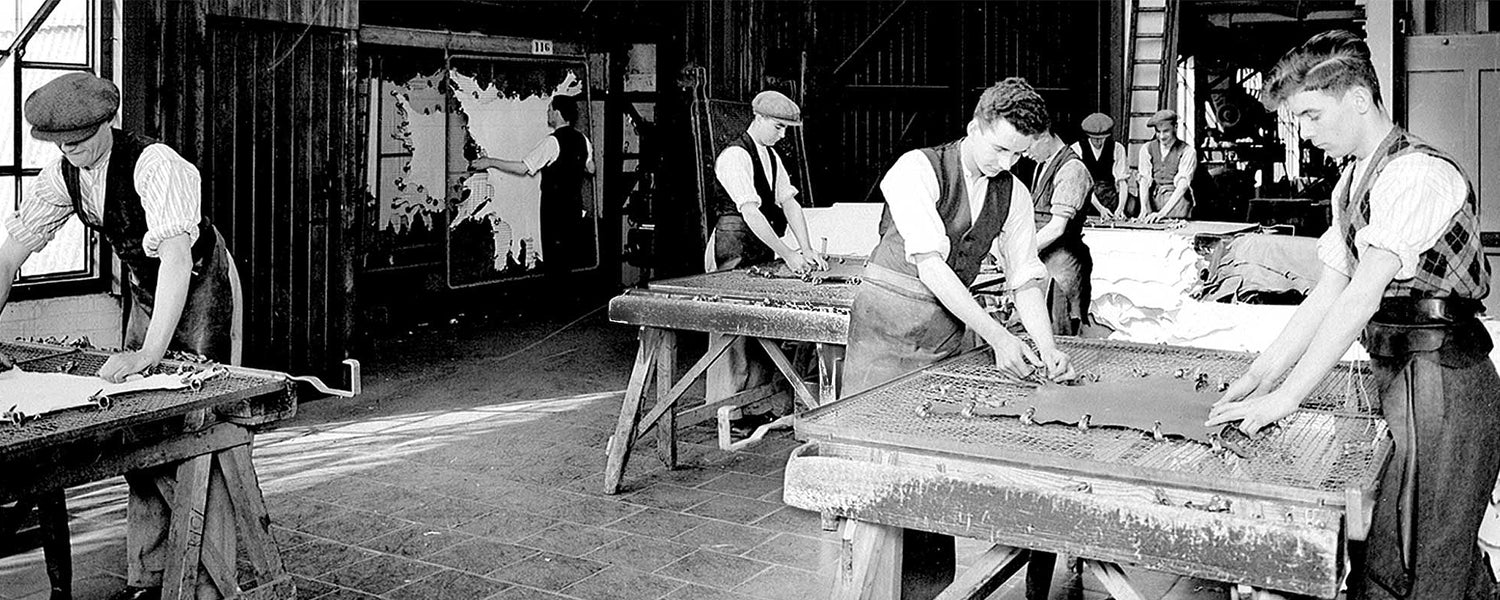

Elizabeth and John Tusting's son, Jack, grew up immersed in the family leather business. At 17, he enlisted in the Royal Flying Corps during World War I. While Jack was stationed in Mesopotamia, his grandfather passed away and the family tannery was sold. Undeterred by this setback, Jack returned home and established his own state-of-the-art tannery in the same village where he grew up. Through determination and hard work, Jack ensured that the Tusting name would endure and be remembered for its excellence in leather craftsmanship.

GOODBYE, SHOES...

Developments in the very same industry that brought the Tusting family into the leather-making business also moved it on. The 1970s recession hit, and shoemakers were forced to move operations to the Far East in order to survive. With too little demand to sustain the business in its current form, the family firm faced a challenge: to survive, the business would need to evolve.

Happily, whichever genes carried Jack Tusting’s indomitable spirit had been passed down through the generations. A two-stage survival plan was put in place: firstly, to leverage the company’s expertise and import the best leather from overseas on behalf of the remaining, and most successful, domestic shoe brands. And secondly, to put those 100 years of passion and skill to first-hand use.

By the late 1980’s, we decided to manufacture our own premium leather goods.

NOW

Today, with Charles Pettit’s great-great-grandson Alistair at the helm, TUSTING is a global name in luxury leather goods. Our busy Lavendon workshop lies just a couple of miles from the original tannery, at the heart of England’s leather country: the juncture between the counties of Northamptonshire, Buckinghamshire and Bedfordshire. It is right here that we create every Tusting item, from flat leather to finished piece.

There are families here whose stories are interwoven with our own: generations of leather experts who have worked for Tusting as long as any of us can remember. You may not have known our history, or how we came to be a globally loved brand. But, if you’ve admired our beautiful leather bags, we hope it’s because you feel the passion and experience that goes into every stitch.

Every bag we sell becomes part of its owner’s story: these are signature pieces that, with the right care, will only become more beautiful over time and are often handed on to the next generation. A wonderful investment, designed to delight for a lifetime.

A DEDICATED TEAM

-

Gillian Tusting

You’ll find Edinburgh graduate of physiology and pharmacology Gillian at the helm for all things brand and customer-related at TUSTING. Brand equity is one of the most valuable things we have here at TUSTING; Gillian uses her wealth of management consultancy experience to manage our customers’ experience and ensure that we never waver from the qualities and values that our customers love so much. When she’s not at her desk – or one of the many events she attends on our behalf – she can be found wandering the countryside on her little pink horse.

-

Alistair Tusting

Following his degree at the University of Cambridge, Alistair spent time working in product design for global power tool and hardware manufacturer Black and Decker.

Perhaps looking for a little more glamour, he was headed to Cranfield Business School to take up a place on an MBA course, but rerouted to join the Tusting family business in 1990, of which he is now the head honcho. When he’s not here at Tusting, Alistair is happiest on a snowy mountain, indulging his love for extreme hill walking.

THE ARTISTRY BEHIND EVERY TUSTING BAG

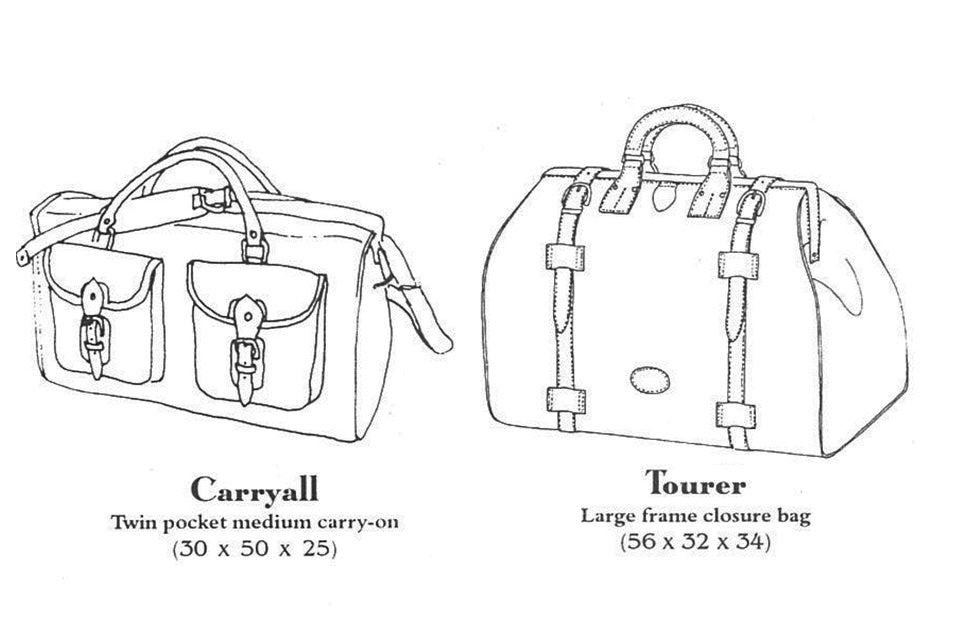

At Tusting, our skilled artisans work in pairs to transform raw leather into exquisite finished designs. This meticulous process involves eight key stages, from pattern making and full-grain leather selection to hand and machine cutting, edge painting, skiving, splitting, and bench-working.

Our expert pattern-makers deconstruct design sketches into as many as 40 separate pattern pieces per bag, while our cutters and edge painters ensure precision before even a single stitch is sewn. Our team of sewing experts hand-finishes each bag, ensuring every product meets the highest standards. At Tusting, every piece is lovingly crafted by human hands.